LEB Ben

Arrogant A-hole At-Large

Gonna sound like a complete newbie here...but can someone teach me a little something. I'm lookin to swap out the 3.55's I have in my Bronco for 4.56's. To my understanding, there is a 4.10 and down and a 4.10 and up carrier.

WTF is the difference between the carriers?

Is it possible to just swap carriers to a 4.10 and up and call it good? I'm thinking no issues here...but I've been wrong before.

If I want to run the same carrier...I can use thick cut gears. What is the difference between 'thick cut' and 'normal' (for lack of a better term).

Should I run the thick cuts or swap carriers?????

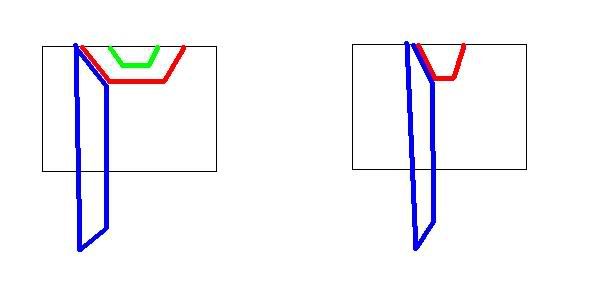

And while we're talking about gears...what's the difference (and what kind of application would use) between 'reverse cut' gears and 'normal gears'?

WTF is the difference between the carriers?

Is it possible to just swap carriers to a 4.10 and up and call it good? I'm thinking no issues here...but I've been wrong before.

If I want to run the same carrier...I can use thick cut gears. What is the difference between 'thick cut' and 'normal' (for lack of a better term).

Should I run the thick cuts or swap carriers?????

And while we're talking about gears...what's the difference (and what kind of application would use) between 'reverse cut' gears and 'normal gears'?