- 885

- 53

No side moldings on the truck But I do know of asitting in the weeds I'll look if get down that way . About 2 hours away.

Thank you Lost.

I have a step bit Buck, might give that a try.

More headway, work is slow so I got time to burn on it.

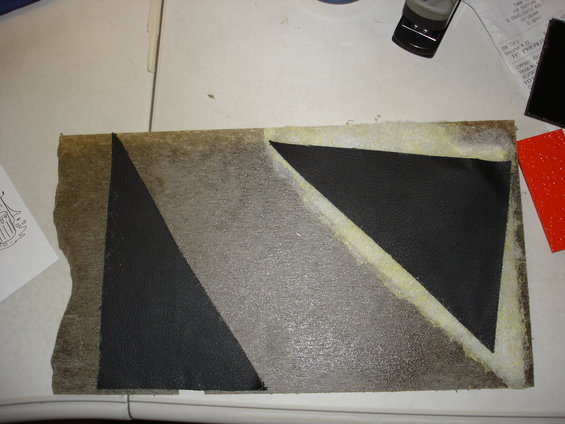

Got the hood sanded with 80 and then went over it with 180. Had a couple of small dents to fix and some rock dents in the front. It is now ready for primer. I have to pull the hood and decide what I'm going to do on the inside. It is the worst part of sanding this truck.

I also took off all the bondo that was covering up a dent in the lower rear corner of the bed. I sure am glad I took all of the prior bondo work off this truck. Whoever did the previous work sucked at preparation.

Passenger doors are on and lined up. Couple small dents in the rear door that needed some attention.

So if I get the back of the cab sanded, the front of the box, fix the dent in the bed and sand down the OE primer on the passenger door and fenders I think it is pretty much ready for some primer.