- 39

- 0

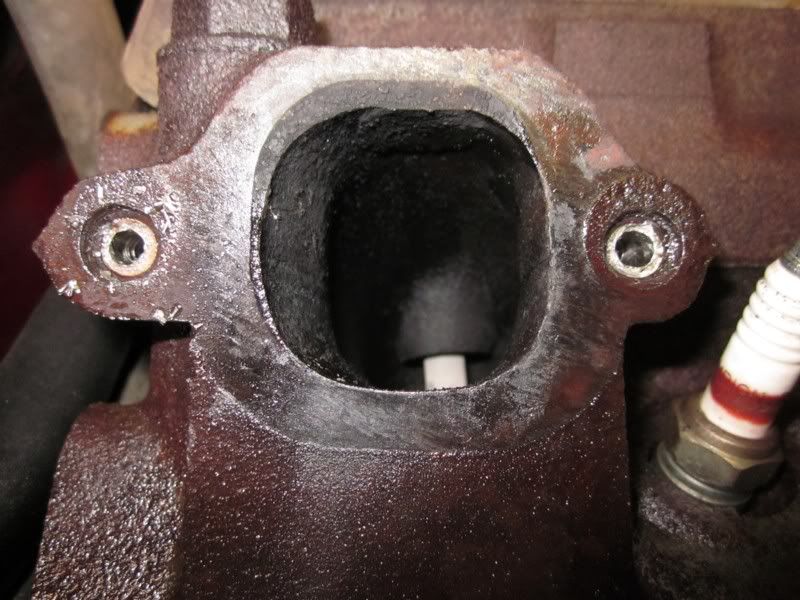

Well, while removing my exhaust manifolds to put a Banks kit on my 1990 F350, (7.5l), I snapped the front bolt on number 8 off flush, (the back one was already flush). I've drilled the hole, and sprayed the heck out of it with liquid wrench. Other than patience, any other advice? I'm a little nervous about using a torch as I've sprayed so much liquid wrench on this thing over the last few days I'm afraid it may go up in flames.