Austin

FTF's #1 Knob Polisher

Here's a how to for ya! (I'd like to contribute a few more as I get the time)

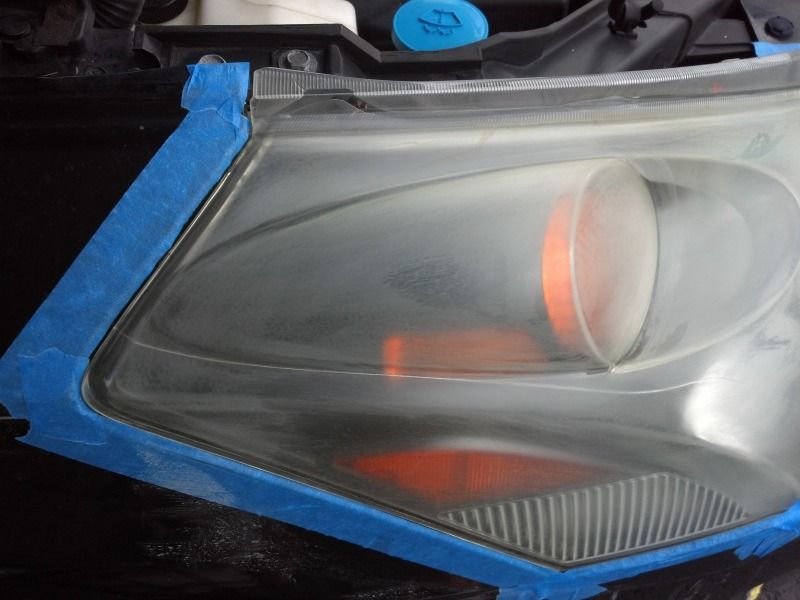

Today I restored the headlights on a Nissan minivan, they were in desperate need of fixing. Today's article will be using several different products, using a few things that may not be readily available at a chain store (I'll cover some alternatives).

What you'll need:

High speed drill (variable)

3M Headlight restoration kit

Compound (Meguiar's Ultimate Compound works well, available at AutoZone or the like)

Polish (Meguiar's Ultimate Polish, read above)

Tape (1/2"-1", depends on how ballsy you are!)

-OPTIONAL- rotary buffer & plastic sealant

Refer to post 2 for the rest of the story!

Today I restored the headlights on a Nissan minivan, they were in desperate need of fixing. Today's article will be using several different products, using a few things that may not be readily available at a chain store (I'll cover some alternatives).

What you'll need:

High speed drill (variable)

3M Headlight restoration kit

Compound (Meguiar's Ultimate Compound works well, available at AutoZone or the like)

Polish (Meguiar's Ultimate Polish, read above)

Tape (1/2"-1", depends on how ballsy you are!)

-OPTIONAL- rotary buffer & plastic sealant

Refer to post 2 for the rest of the story!