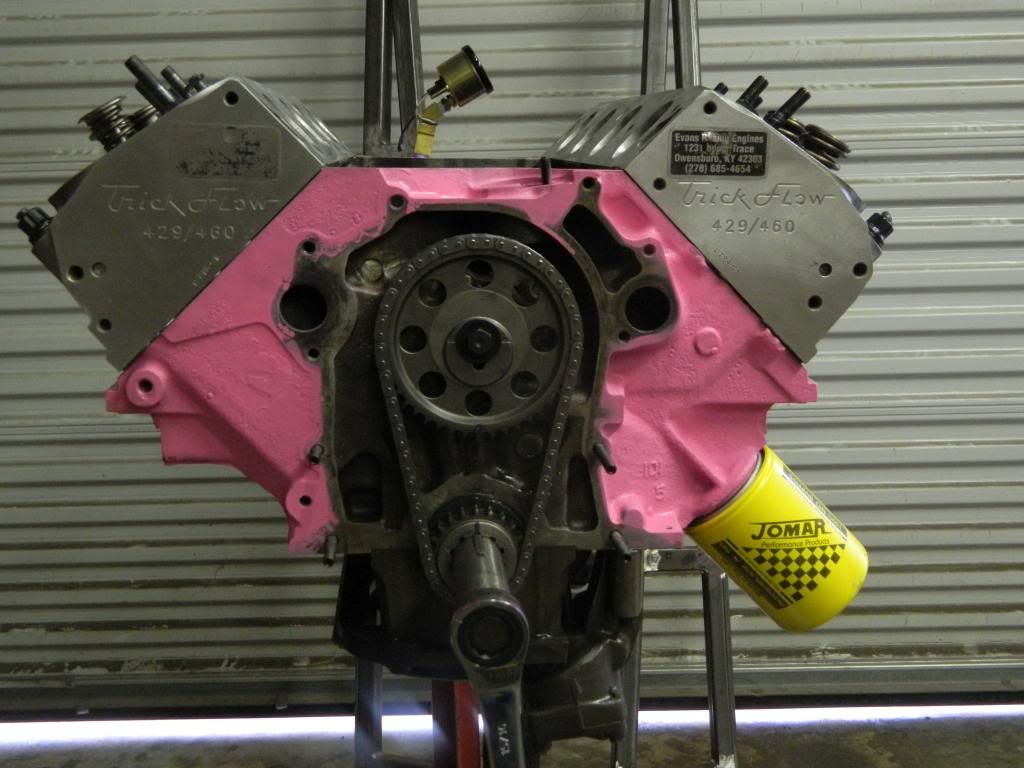

It seems for the past several years Ive only built trucks/engines for other people. This winter its finally my turn. All prep and assembly is done in house here at Left Eye Blind with balance and machine work done by a very reputable, race oriented, machine shop.

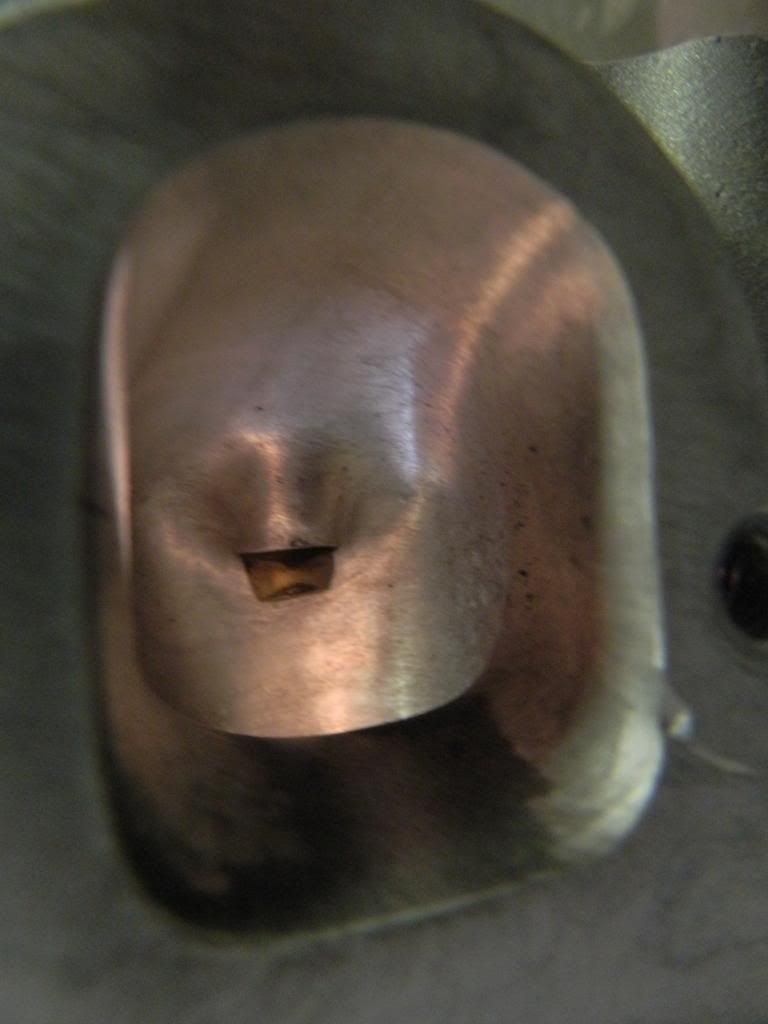

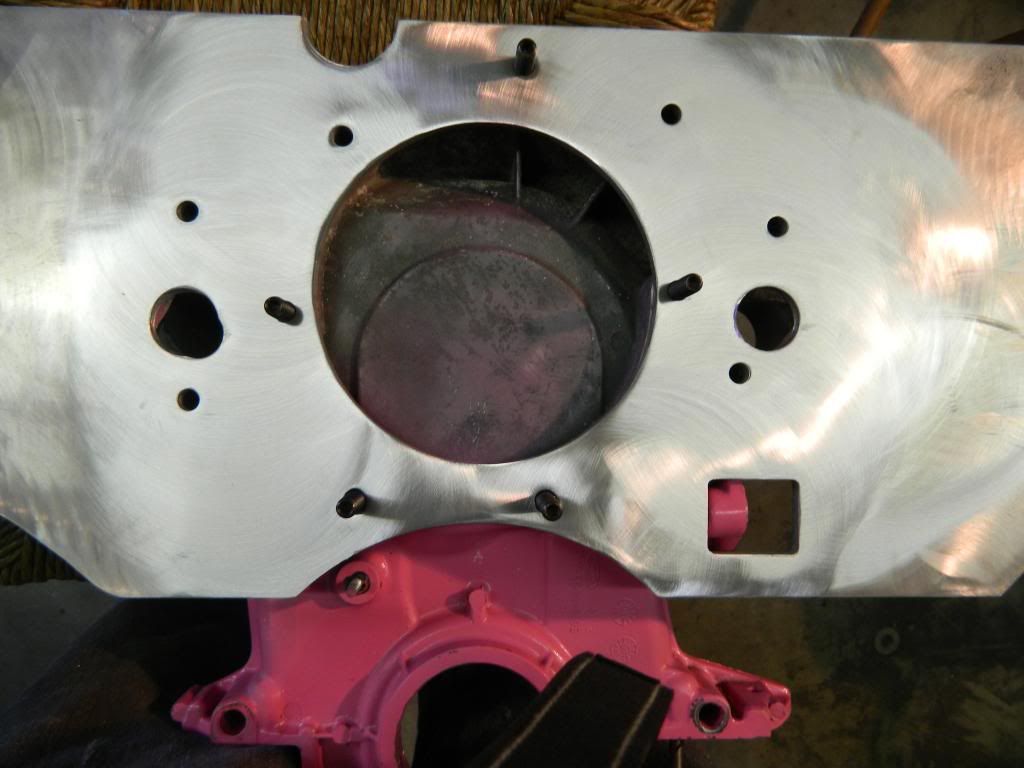

Block prep. Oil galley smoothed and rear drain backs enlarged and radiused. I have also added a front oil drain back hole, enlarged the filter inlet and added a direct oiling port to the distributor gear - yes these mods mean drilling holes in your block while avoiding your water and oil passages.

Front drain back

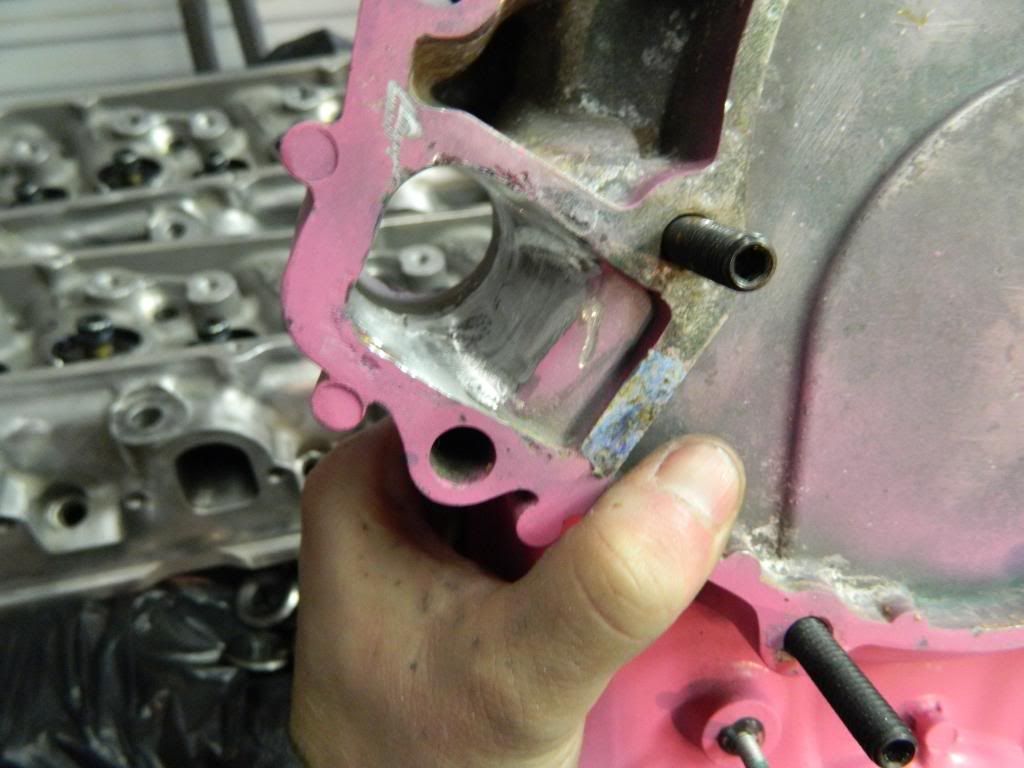

Gauge

Another thing we did was tap the freeze plug holes to accept NPT pipe plugs. Adds some rigidity to the block and less likely for the drive in plugs to pop out under load or block twist(yeah it happens at higher horsepower levels) with motor plates.

ARP main, head and oil pump studs installed and also added a block mounted oil pressure gauge.

We only use King engine bearings, Felpro/FRPP gaskets and Jomar non-bypass oil filters on all LEB street and race engines. These are King HP pro series bearings and a FRPP gasket set with one piece oil pan gasket and Cometic valve cover gaskets.

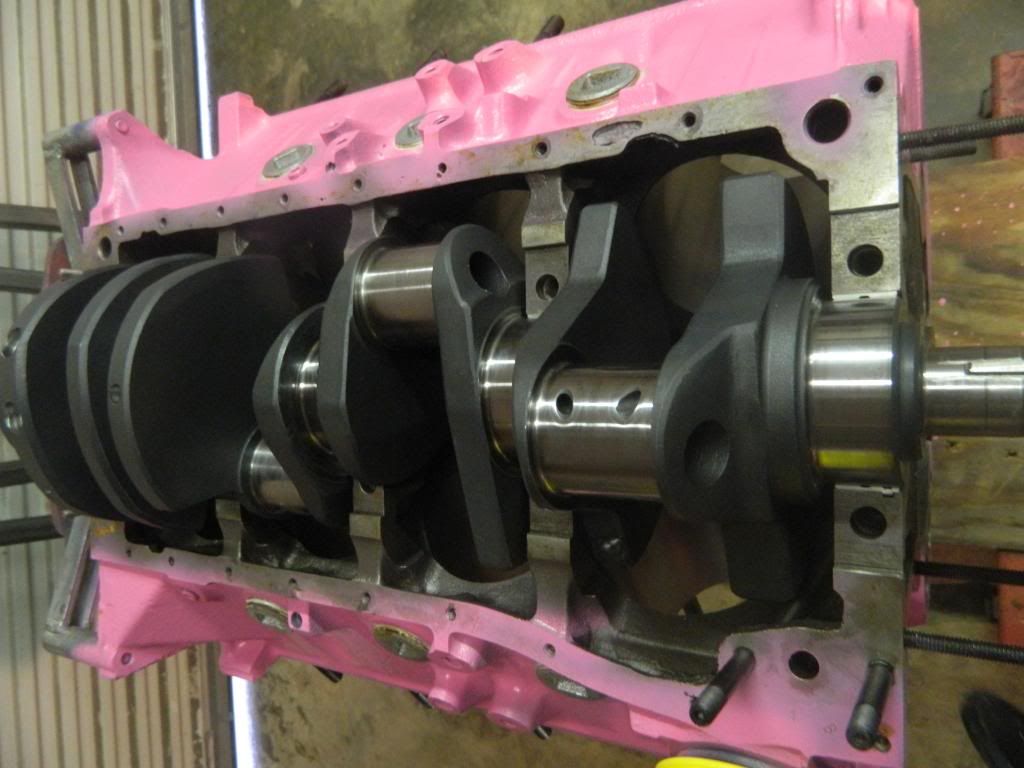

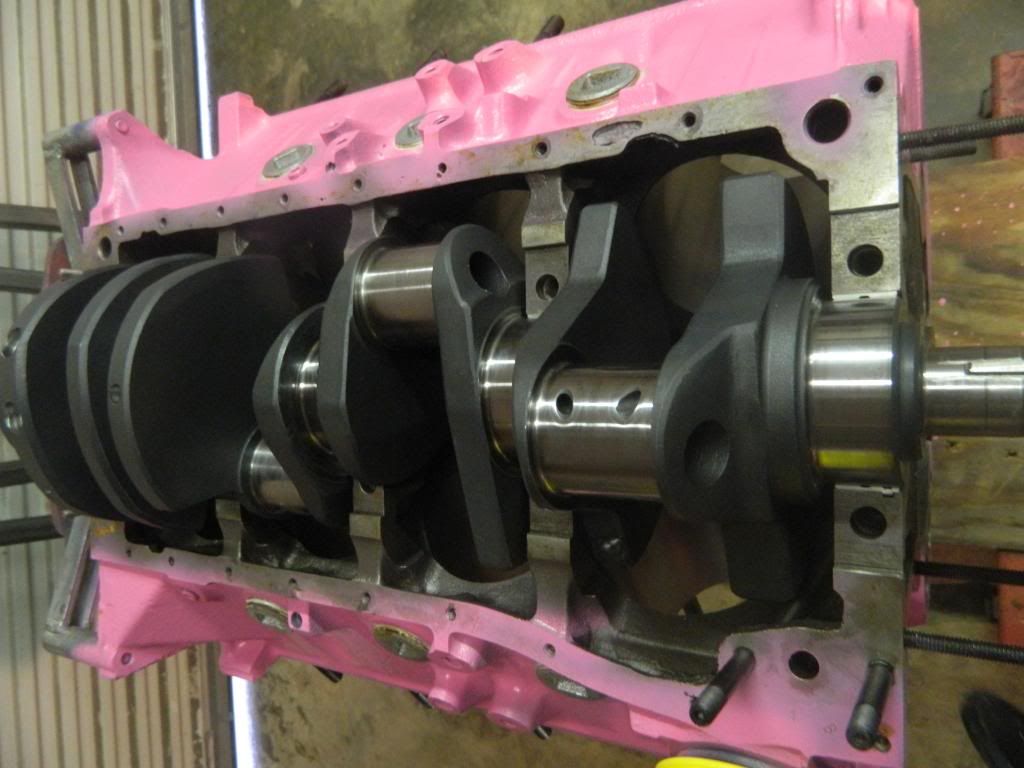

Forged 4.300" crank balanced to 9000rpm.

Canton main girdle. The front driver side is windowed for use with the Kaase oil pump. The ARP main studs will not work with this girdle so I bought ARP main bolts +.500" instead. If anyone is interested I will sell the main studs pictured above for $75 shipped - in factory box with ARP moly lube and sticker. Mock up time only. Never ran.

Kaase high volume oil pump and ARP drive shaft. Some clearance was required to miss the larger stroke.

Diamond forged -20cc pistons and 6.800" H-beam rods with ARP2000 rod bolts. Lightest piston matched to the heaviest rod and balanced to 9000rpm. Hellfire heavy NOS top ring and Akerly and Childs Xtreme 2nd ring and low tension oil ring packs. This combo at zero deck will make 11.2:1 comp.

All together and Canton windage tray mounted directly to the girdle. No clearancing was necessary to fit around the larger Kaase pump.

Block prep. Oil galley smoothed and rear drain backs enlarged and radiused. I have also added a front oil drain back hole, enlarged the filter inlet and added a direct oiling port to the distributor gear - yes these mods mean drilling holes in your block while avoiding your water and oil passages.

Front drain back

Gauge

Another thing we did was tap the freeze plug holes to accept NPT pipe plugs. Adds some rigidity to the block and less likely for the drive in plugs to pop out under load or block twist(yeah it happens at higher horsepower levels) with motor plates.

ARP main, head and oil pump studs installed and also added a block mounted oil pressure gauge.

We only use King engine bearings, Felpro/FRPP gaskets and Jomar non-bypass oil filters on all LEB street and race engines. These are King HP pro series bearings and a FRPP gasket set with one piece oil pan gasket and Cometic valve cover gaskets.

Forged 4.300" crank balanced to 9000rpm.

Canton main girdle. The front driver side is windowed for use with the Kaase oil pump. The ARP main studs will not work with this girdle so I bought ARP main bolts +.500" instead. If anyone is interested I will sell the main studs pictured above for $75 shipped - in factory box with ARP moly lube and sticker. Mock up time only. Never ran.

Kaase high volume oil pump and ARP drive shaft. Some clearance was required to miss the larger stroke.

Diamond forged -20cc pistons and 6.800" H-beam rods with ARP2000 rod bolts. Lightest piston matched to the heaviest rod and balanced to 9000rpm. Hellfire heavy NOS top ring and Akerly and Childs Xtreme 2nd ring and low tension oil ring packs. This combo at zero deck will make 11.2:1 comp.

All together and Canton windage tray mounted directly to the girdle. No clearancing was necessary to fit around the larger Kaase pump.