95F350XL

Master Junk Tech

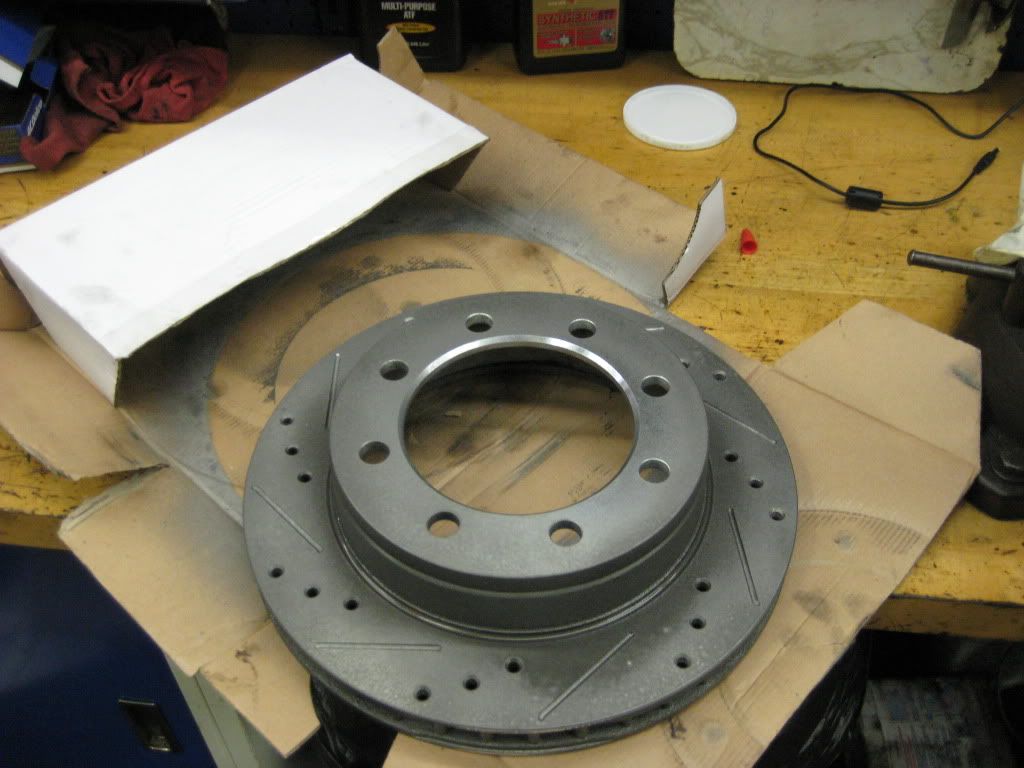

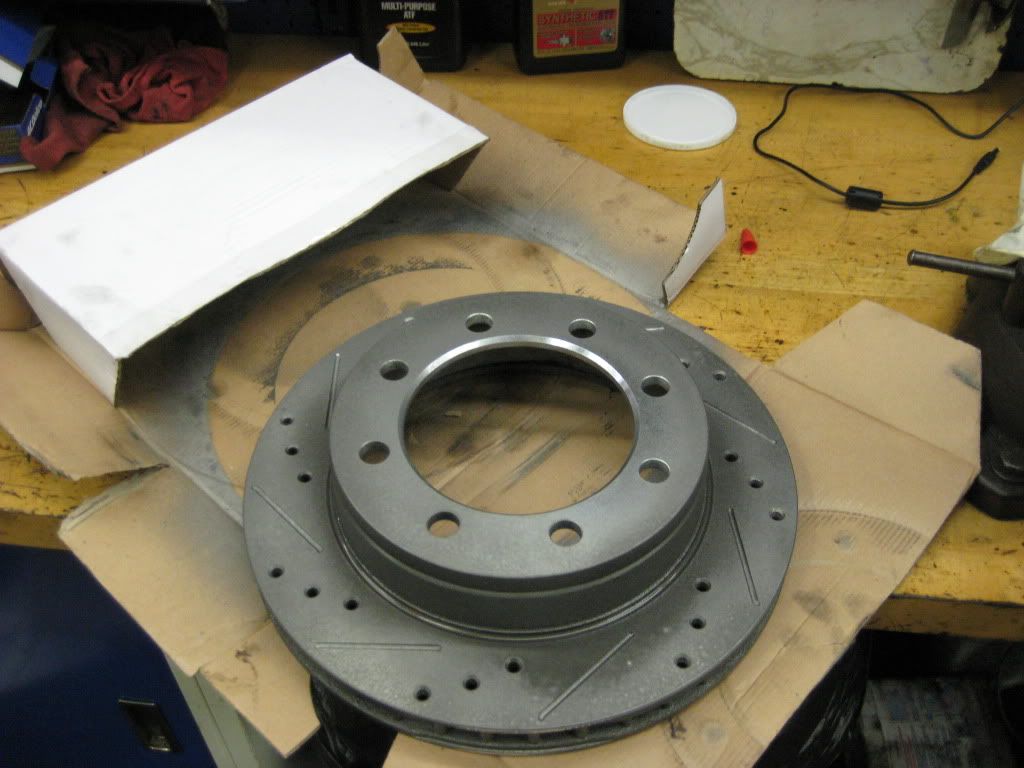

Ok so my rotors were warped on the truck, not very bad, but I wanted to get my self something for my bday and this was it. Got the kit off ebay and it looks to be good. Got 2 rotors and pads(didnt install, just did loaded calipers)

Anyway

Take the Hub Twist Cap off

On my style there was a phillips screw holdin the peice that connects the axle shaft to the hub, and the peice pops out with a giant spring. Never seen this before, never done a F350 hub before so I guess everthing is bigger.

Take the big clip out of the hub, then usin 2 of the cap screws pull the center peice out.

Now you can take the bearings out, using the special took losen the outer lock ring and take it out

Take the lock spacer out

Take the inner lock ring out and hold the rotor so it doesnt slide off and fall on you or the floor.

Slide hub asembly off the spindle

Gettin the rotor and hub seperated

Hammer the studs out of the hub and rotor asemble. I used a punch and hammer.

Then there is 2 spots you hammer a chisel in and seperate the hub from the rotor

If your goin to do bearings now is the time, pop the seal out, clean out the hub, and put in new bearings and races. I did this, and when I took the rotor off, 1/2 the grease seal was still on the spindle.

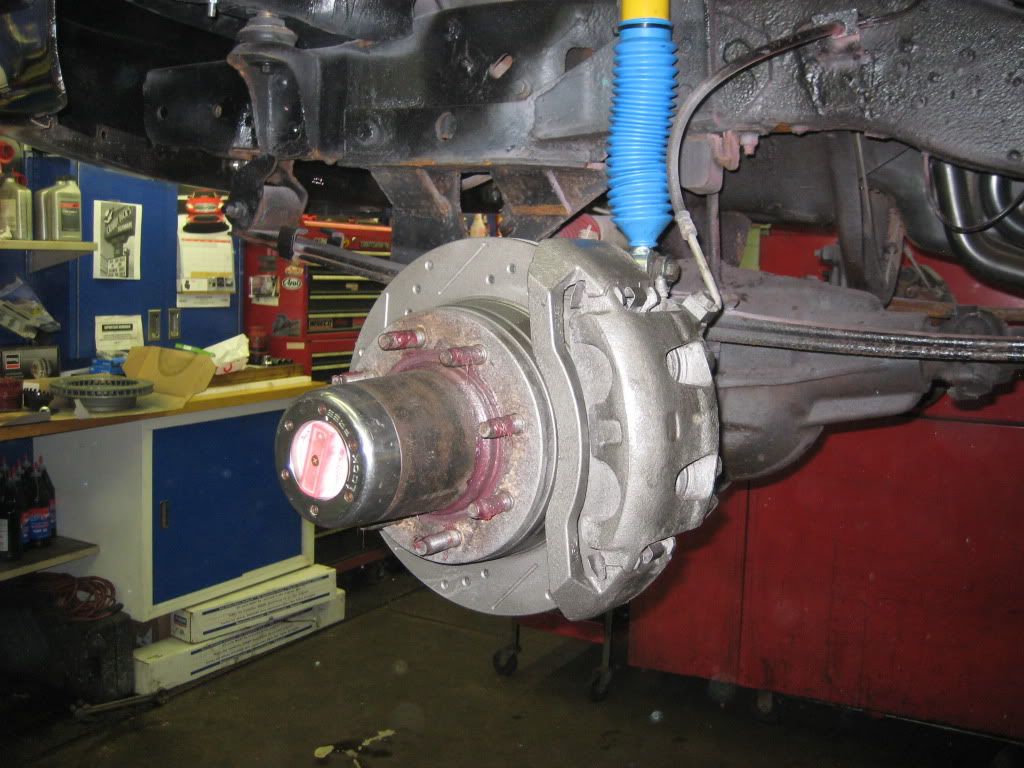

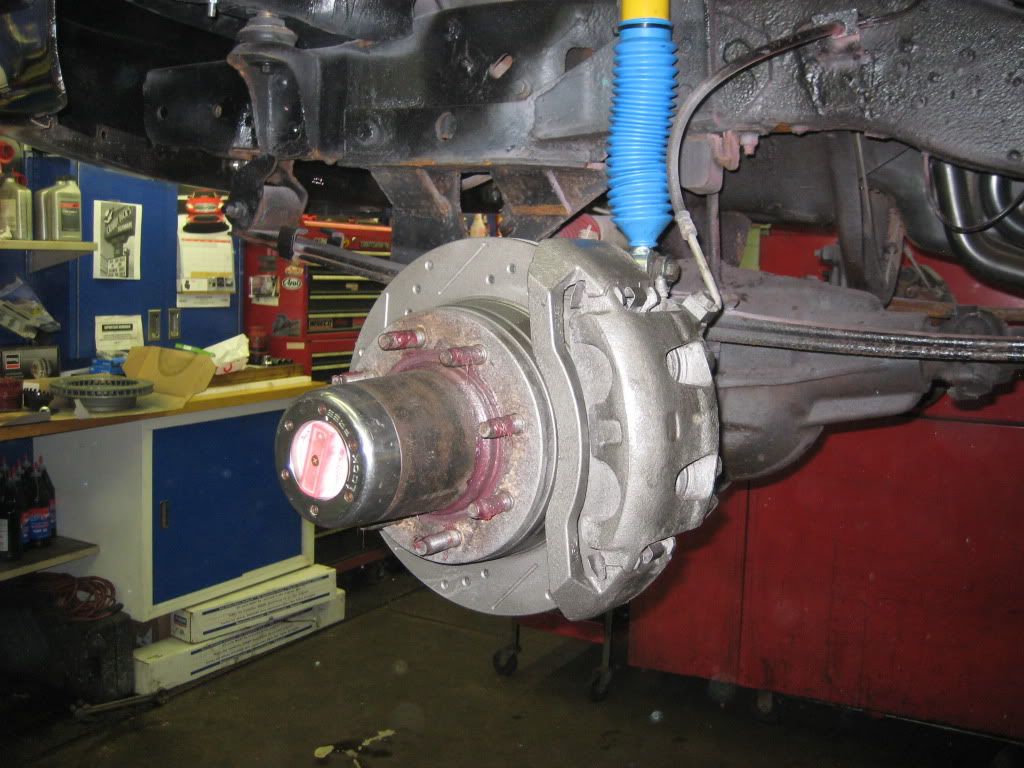

Install

I grease around where the rotor and hub meet, then put the rotor on top, and grease up the studs and hammer them back in, I have a tool that installs on the other side of the stud and you use the lug nut and impact to pull the studs through, works awesome.

The rest is reverse of removal.

I spray paint the rotors front and back, inside and on top, I dont like to see rust, so this will help keep it nicer longer(plus looks better through my wheel)

Also wirebrushed the calipers and bridges and sprayed em up too.

PICS

Old

I had to cut backing plate off as it was so rotted out.

Anyway

Take the Hub Twist Cap off

On my style there was a phillips screw holdin the peice that connects the axle shaft to the hub, and the peice pops out with a giant spring. Never seen this before, never done a F350 hub before so I guess everthing is bigger.

Take the big clip out of the hub, then usin 2 of the cap screws pull the center peice out.

Now you can take the bearings out, using the special took losen the outer lock ring and take it out

Take the lock spacer out

Take the inner lock ring out and hold the rotor so it doesnt slide off and fall on you or the floor.

Slide hub asembly off the spindle

Gettin the rotor and hub seperated

Hammer the studs out of the hub and rotor asemble. I used a punch and hammer.

Then there is 2 spots you hammer a chisel in and seperate the hub from the rotor

If your goin to do bearings now is the time, pop the seal out, clean out the hub, and put in new bearings and races. I did this, and when I took the rotor off, 1/2 the grease seal was still on the spindle.

Install

I grease around where the rotor and hub meet, then put the rotor on top, and grease up the studs and hammer them back in, I have a tool that installs on the other side of the stud and you use the lug nut and impact to pull the studs through, works awesome.

The rest is reverse of removal.

I spray paint the rotors front and back, inside and on top, I dont like to see rust, so this will help keep it nicer longer(plus looks better through my wheel)

Also wirebrushed the calipers and bridges and sprayed em up too.

PICS

Old

I had to cut backing plate off as it was so rotted out.