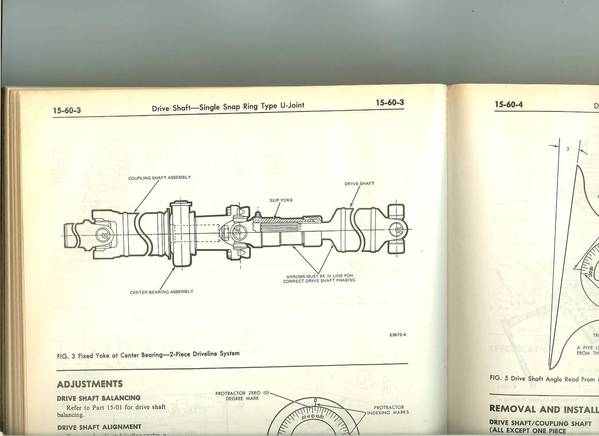

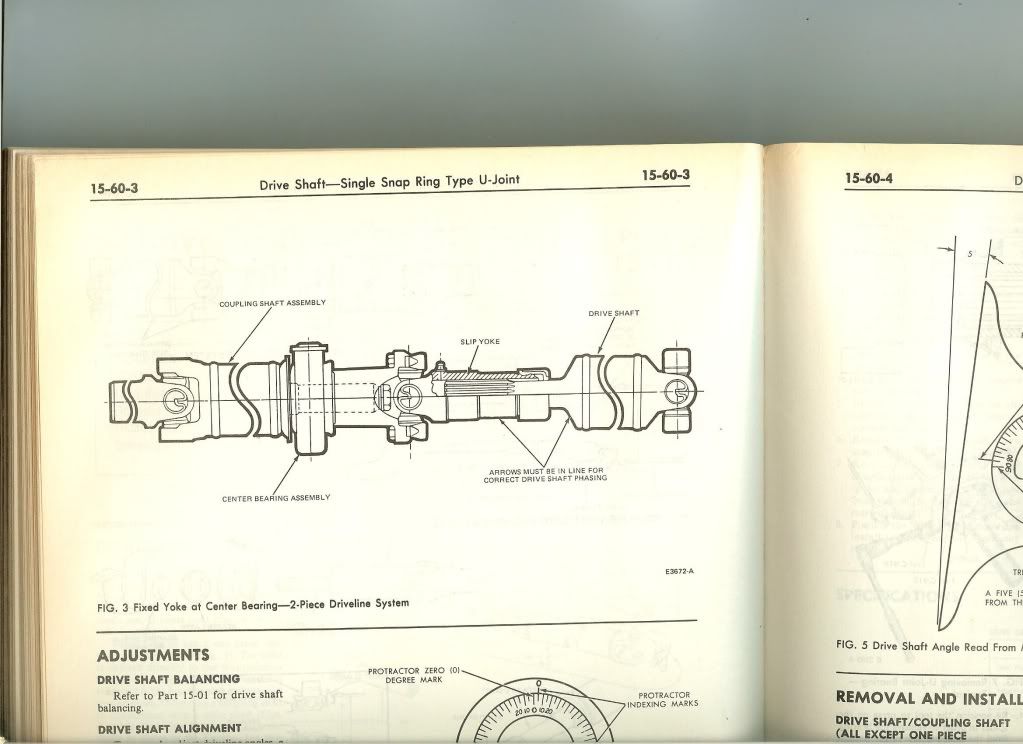

I ran into a snag while trying to line up the universal caps (snap rings) on my two piece DS. On the front shaft, rear splines/yoke, the yoke will end up 1 gear off of being lined up. (I had it 90* out ). And I can't find anything in the shop manual other then lining up the universal caps. Anybody know another way ?

![Confused [confused] [confused]](/old/forum/images/smilies/confused0082.gif)