Sparky83

Virginia Chapter member

tried to do some diagnosis today but today it behaved... the only thing i can see though is the high side seems to read higher than the reference chart... not sure what to make of that...

Little breakdown of the issue... since changing the compressor last summer (not this summer) ive been having issues with the a/c in my stang... only things i changed were the compressor and oriface tube... i did not... REPEAT DID NOT!!! have the compressor mechanically fail... reason the compressor was changed was because the seal on the input shaft for the compressor went bad letting the freon escape out behind the clutch.. had added some periodically whenever the system quit running every couple months the year before... last year i finally found where the leak was to know what to change... (year before it wasnt showing up guessing it got big enough that the dye finally started to show up).. system still had some pressure when i disconnected the compressor to change it...

after changing the compressor and oriface tube the a/c ran great for few months... then suddenly started tripping the over pressure pop-off valve when the system would engage... usually did it once or twice then ran without an issue... (originally i thought the clutch was slipping when it went to engage.. wasnt till couple months ago i figured out what was really happening with the noise i was hearing but at that time didnt have time to look at it..) when it got really hot out (as in kissing or being over 100*) it just did it repeatedly and wouldnt stay engaged... so just didnt use it.. now that i got time to look at it the systems working fine... so am confused now... when i hooked the gauges up today heres what i saw...

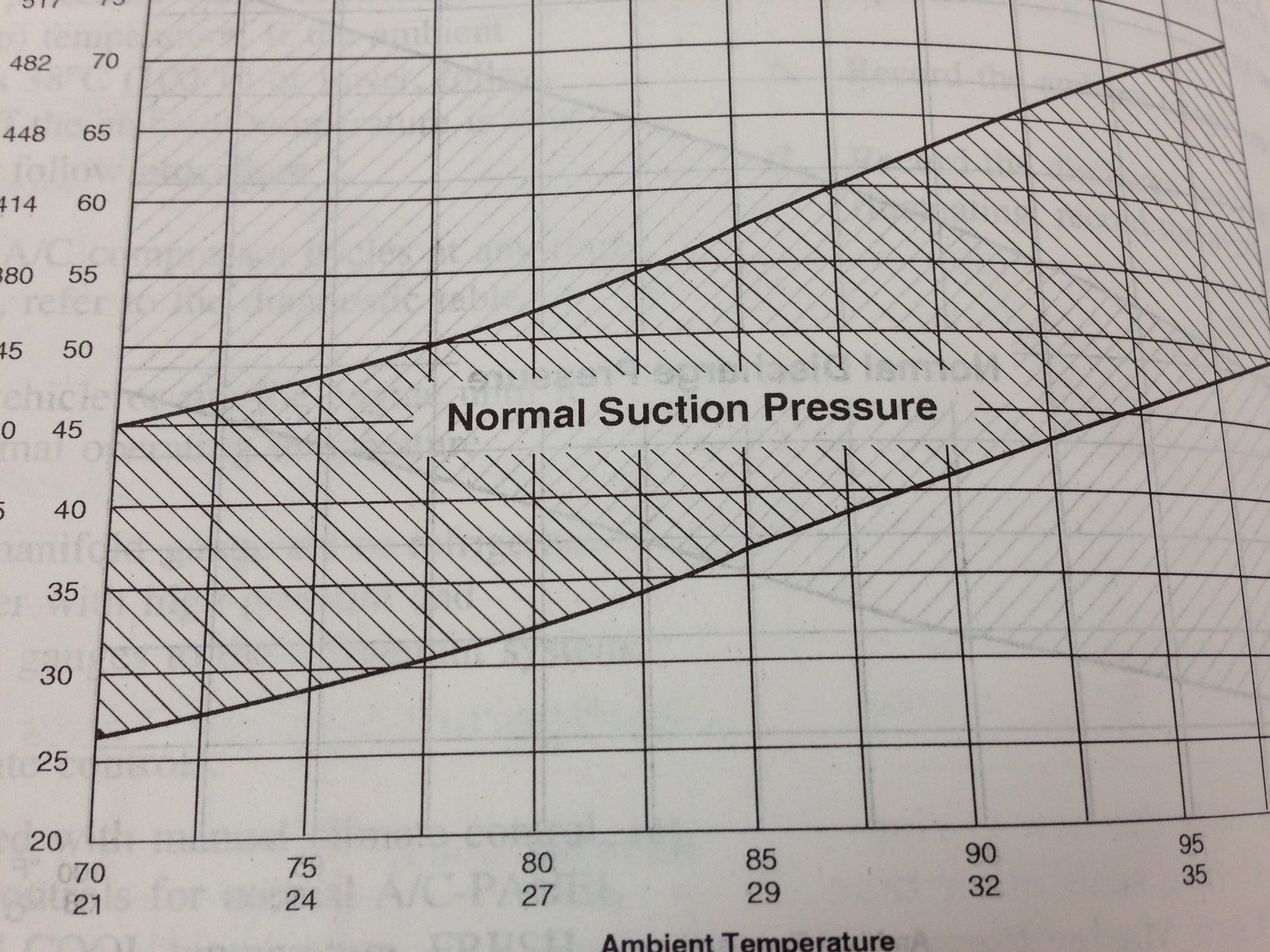

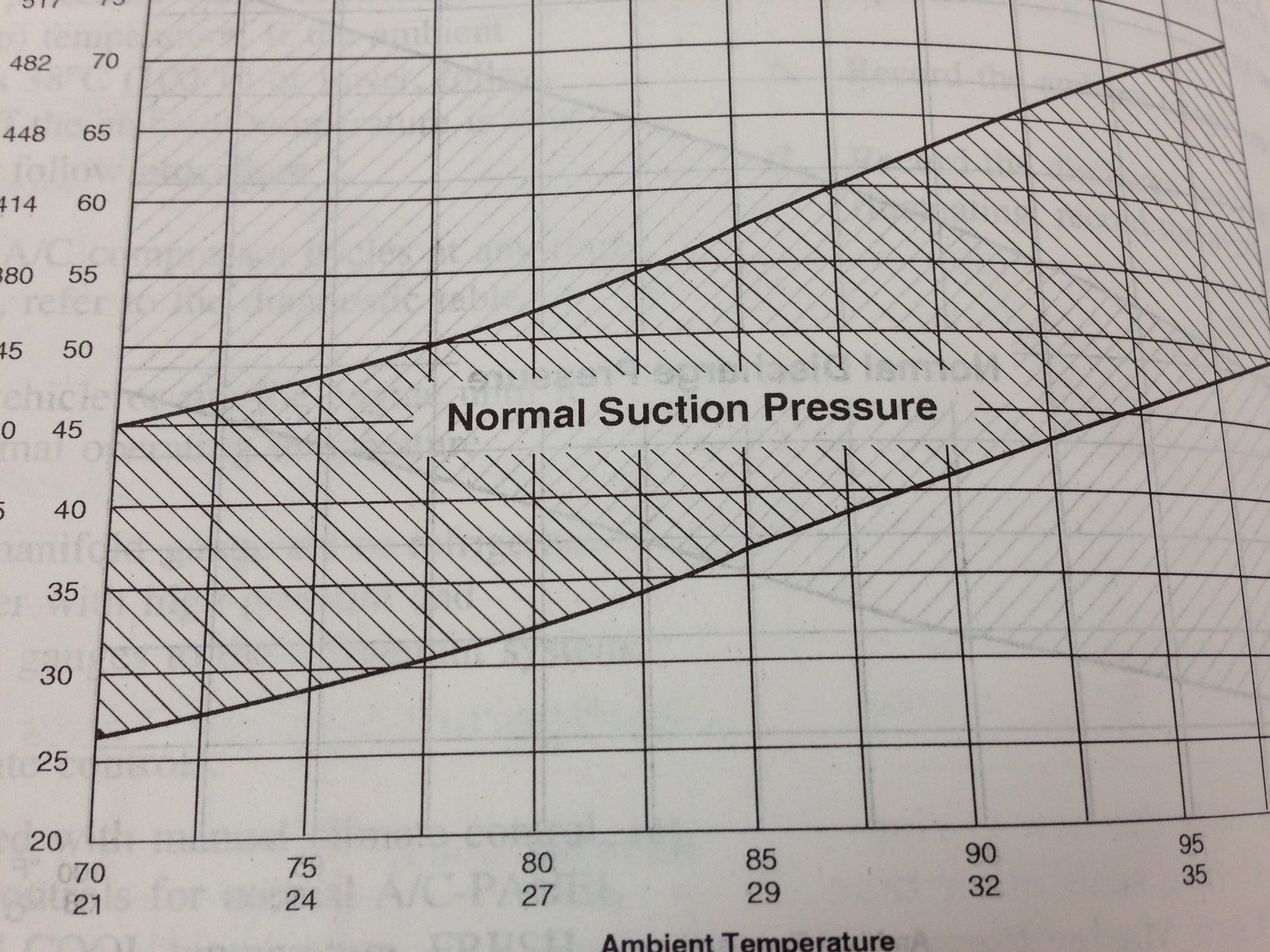

84*F today when i went to play with the system.. so used 85* for the reference... low side seems to be just a couple psi higher for what it says for the middle of the reference chart.. which i get there can be a variance of a couple psi there so long as its between the high and low section...

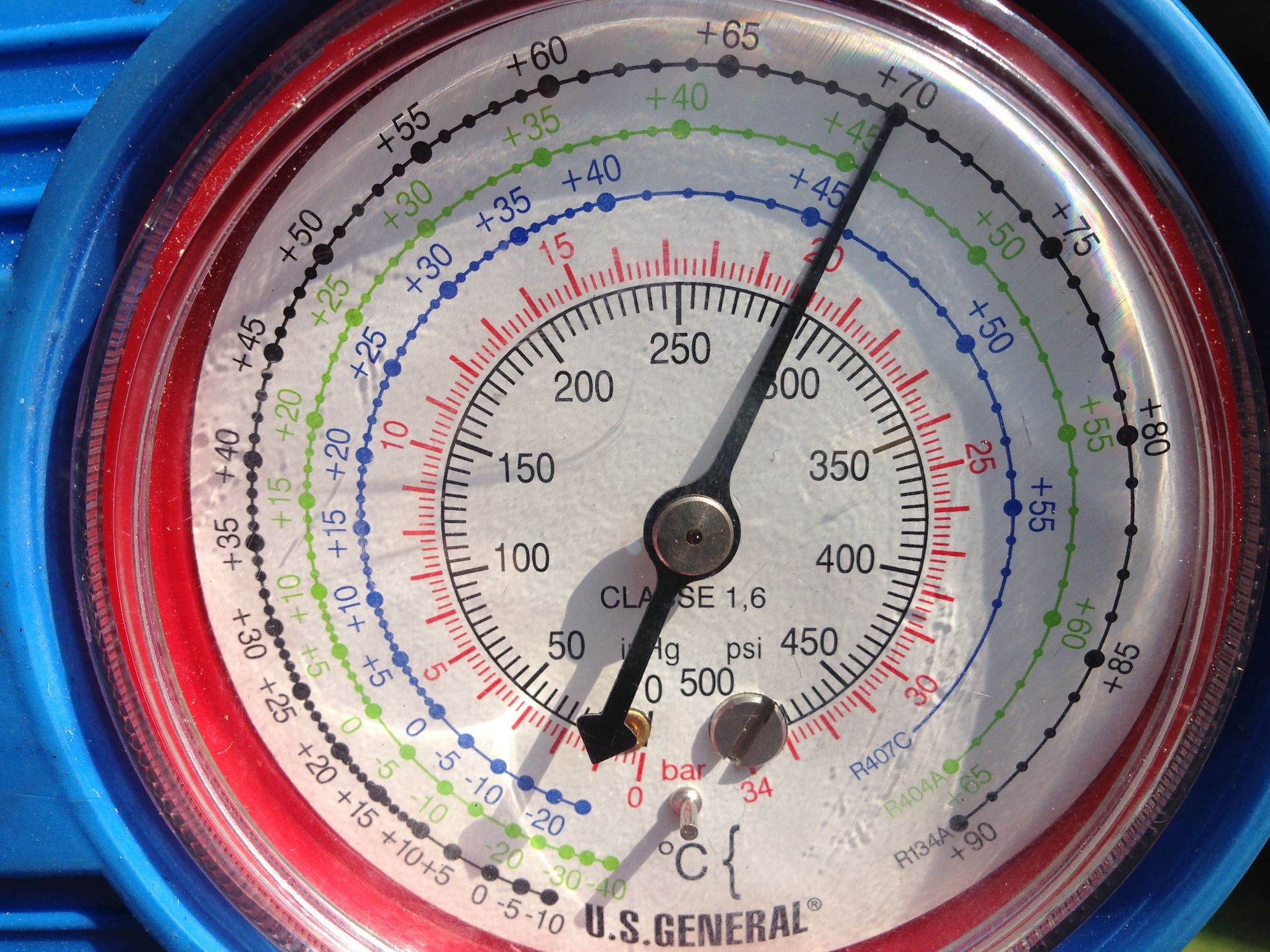

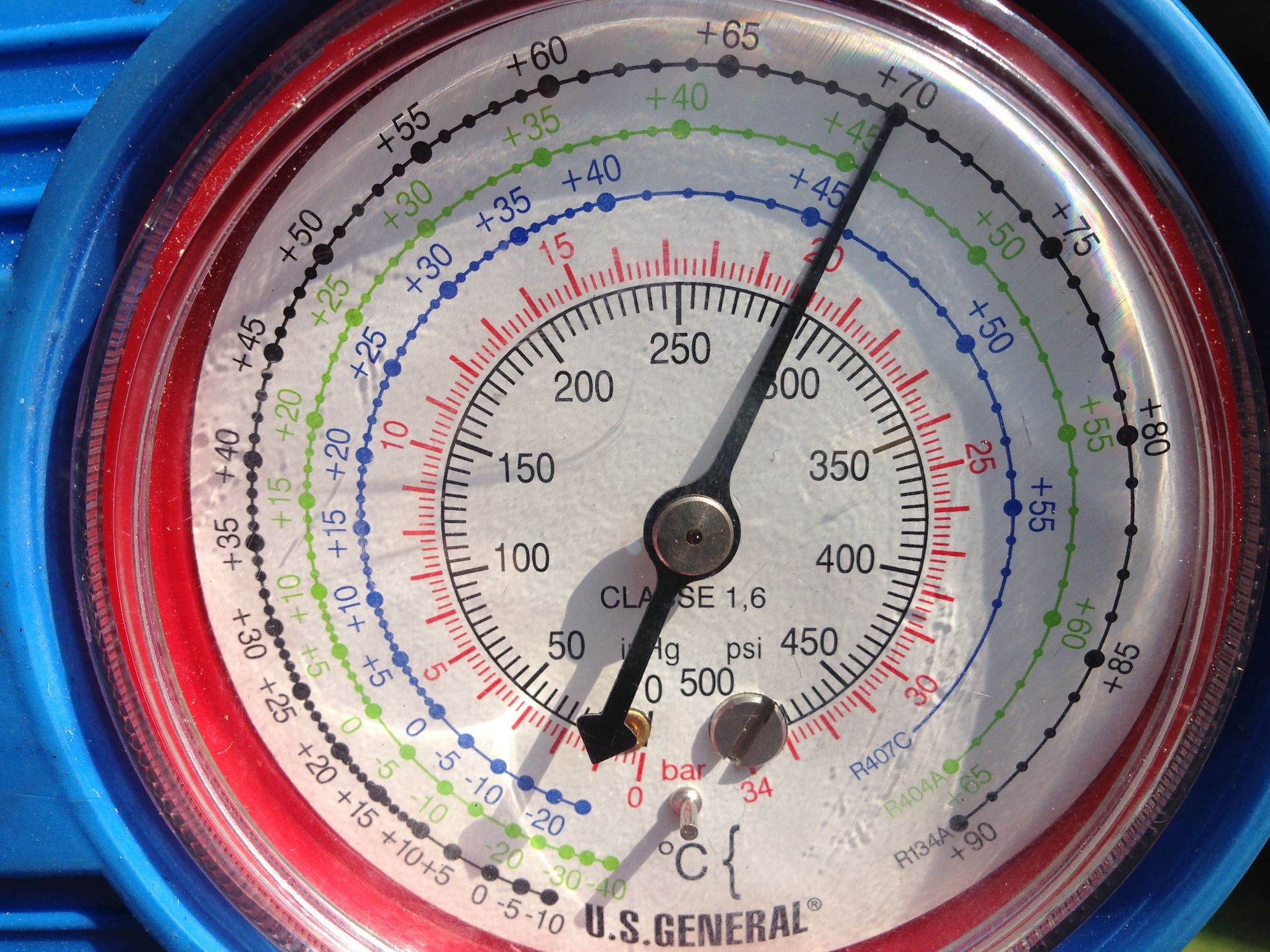

high side is reading around 290 but according to the chart should be around 225 -275 at the highest for the temp today... wondering how accurate the charts really are.. but has me concerned some... wondering why when the low sides pretty much dead center of the range that the high side would be 40-50 over the mid point of the chart...

ironically since it decided to work today output is around 47* inside... when i would run down the highway after i installed the compressor it would get down to 38 before but i didnt run it down the highway today... so i dunno.. today worked fine which makes it hard to troubleshoot... but dunno why it was tripping the high pressure valve or why the high sides reading more along the high spec for 90* than 85...

Little breakdown of the issue... since changing the compressor last summer (not this summer) ive been having issues with the a/c in my stang... only things i changed were the compressor and oriface tube... i did not... REPEAT DID NOT!!! have the compressor mechanically fail... reason the compressor was changed was because the seal on the input shaft for the compressor went bad letting the freon escape out behind the clutch.. had added some periodically whenever the system quit running every couple months the year before... last year i finally found where the leak was to know what to change... (year before it wasnt showing up guessing it got big enough that the dye finally started to show up).. system still had some pressure when i disconnected the compressor to change it...

after changing the compressor and oriface tube the a/c ran great for few months... then suddenly started tripping the over pressure pop-off valve when the system would engage... usually did it once or twice then ran without an issue... (originally i thought the clutch was slipping when it went to engage.. wasnt till couple months ago i figured out what was really happening with the noise i was hearing but at that time didnt have time to look at it..) when it got really hot out (as in kissing or being over 100*) it just did it repeatedly and wouldnt stay engaged... so just didnt use it.. now that i got time to look at it the systems working fine... so am confused now... when i hooked the gauges up today heres what i saw...

84*F today when i went to play with the system.. so used 85* for the reference... low side seems to be just a couple psi higher for what it says for the middle of the reference chart.. which i get there can be a variance of a couple psi there so long as its between the high and low section...

high side is reading around 290 but according to the chart should be around 225 -275 at the highest for the temp today... wondering how accurate the charts really are.. but has me concerned some... wondering why when the low sides pretty much dead center of the range that the high side would be 40-50 over the mid point of the chart...

ironically since it decided to work today output is around 47* inside... when i would run down the highway after i installed the compressor it would get down to 38 before but i didnt run it down the highway today... so i dunno.. today worked fine which makes it hard to troubleshoot... but dunno why it was tripping the high pressure valve or why the high sides reading more along the high spec for 90* than 85...