TexasNomad

FTFS Designated DRINKER!

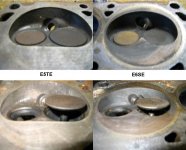

Hiya guys, well I picked up my heads to day they are in great shape valves look clean chambers look good. I want to port them but really don't know how far I can go, they have these really nasty EGR bumps I mean damn why not just plug the exhaust ports why don'tcha , how far can I grind those off with out hitting the water jackets? beside the egr bumps what else would be a good thing to grind/shine up? thanks for any help you can give me guys