I have been asked many times how to test a PIP Sensor by itself so here is what I came up with.

Playing at the bench this weekend with a Distributor and PIP Sensor and here is what I found out about testing a PIP Sensor.

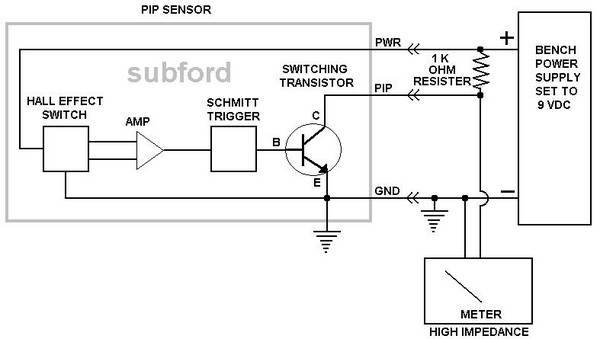

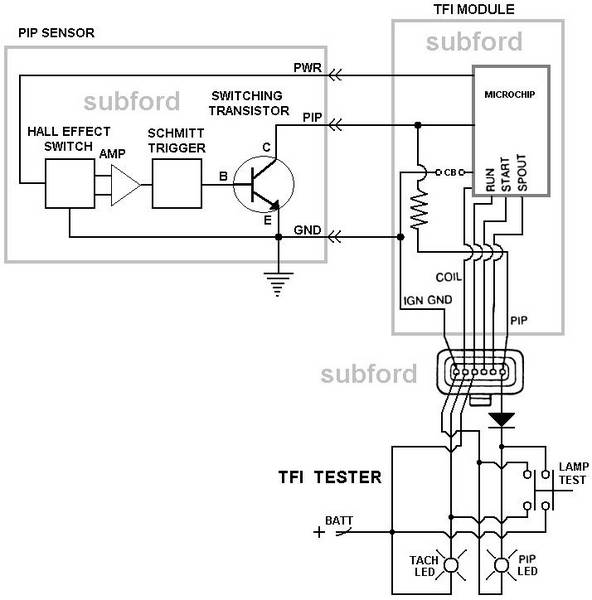

The PIP Sensor just has an off and on output but to test it you have to put voltage on the PIP at the plug through a voltage-dropping resistor.

I hooked it up like the diagram below and turned the distributor slowly by hand.

The meter went to full voltage and dropped back to zero as I turned the distributor.

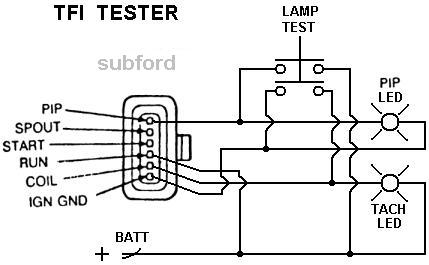

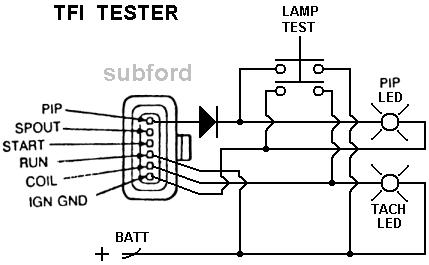

I did not have a TFI (ICM) module hooked to it during the tests as I wanted to come up with a test to find out if it was the PIP or the TFI that was bad.

This would work to test the PIP Sensor if you had no spark. But if it quit while the engine is warm then you could put a hair dryer on the PIP and crank the engine to test it.

You can also use the 12 Volt Battery in the truck for this test but I was thinking about a 9V battery and a LED at the time I did the test.

Ford truck enthusiast forum - FTF

/

Playing at the bench this weekend with a Distributor and PIP Sensor and here is what I found out about testing a PIP Sensor.

The PIP Sensor just has an off and on output but to test it you have to put voltage on the PIP at the plug through a voltage-dropping resistor.

I hooked it up like the diagram below and turned the distributor slowly by hand.

The meter went to full voltage and dropped back to zero as I turned the distributor.

I did not have a TFI (ICM) module hooked to it during the tests as I wanted to come up with a test to find out if it was the PIP or the TFI that was bad.

This would work to test the PIP Sensor if you had no spark. But if it quit while the engine is warm then you could put a hair dryer on the PIP and crank the engine to test it.

You can also use the 12 Volt Battery in the truck for this test but I was thinking about a 9V battery and a LED at the time I did the test.

Ford truck enthusiast forum - FTF

/

Last edited: